SYSTEM COMPONENTS

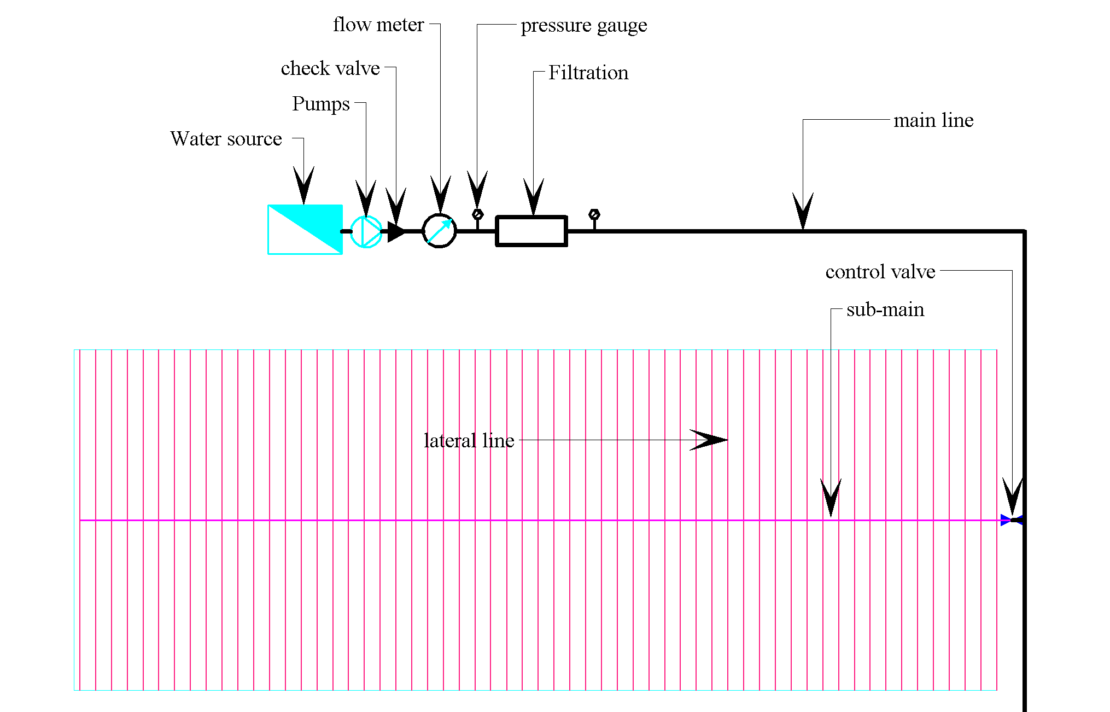

Irrigation system is made up of various components: a pump or pressurized water source, filtration unit, main line, sub-main, manifold, valves, fittings and lateral lines where the emitter devices are located.

Additional equipment often used with irrigation systems include pressure gauges, backflow prevention devices, check valves, flow meter, air vent, fertilizer injectors, automatic timers, soil moisture monitoring devices and others.

SYSTEM COMPONENTS

Water source

Pumps

Filtration

Chemical injector

Distribution pipelines

Emitters

Monitoring and control equipment

Water Source

The water source for irrigation systems can be a well, irrigation canal, reservoir, river, lake, holding tank or municipal water connection. The quantity and quality of the water source needs to be determined for the initial design.

There are basically two main types of water sources: groundwater and surface water:

Many existing and potential water supply sources for irrigation systems are derived from surface water, which does not tend to have high levels of salts.

Groundwater is generally of higher quality than surface water. However, iron and manganese levels should be measured, as high levels may lead to dripper clogging.

Pumps

The type of pump selected for the irrigation systems depends on the water source, amount of lift from the intake to the pump, and requirements for pressure and volume.

Unless the water at the source is supplied at an adequate flow rate and pressure, a pump will be needed to push water from the source through the pipes and drippers.

Most irrigation systems include pumps as an integral part of the drip irrigation system.

Poor pump selection can lead to high operating costs and shortened pump life; this in turn impacts on the performance and reliability of the whole irrigation system.

Filtration

The filtration of the irrigation water is essential in order to avoid blockage damage to the micro-irrigation emitters. The type of filter used depends on the kind of impurities contained in the water and the degree of filtration required on the emitters. Their size should be the most economical with the lowest friction losses ranging from 0.3-0.5 bars.

Water quality can be greatly affected by physical, chemical and biological contaminants that may cause emitter plugging. Therefore, a properly designed, reliable filter is one of the most important parts in the irrigation system. There are several types of filters used alone or in combination with one another for effective filtration of contaminants. Selection of a filter depends on the size of the emitter’s opening (emitter manufacturers have specific filter size recommendations), on the flow rate of the irrigation system and on the amount and type of contaminant to be filtered from the water source. Filters should be sized to remove particles 1/10 of the diameter of the smallest opening in the emitter flow path.

Filtration is critical in any drip irrigation system. Effective filtration is essential for proper irrigation system operation and long-term performance, as it prevents the irrigation water from clogging the drippers.

Fertigation Equipment

Fertilizers are applied with the irrigation water through the system using special devices called fertilizer injectors installed at the head control. There are three main types of fertilizer injectors: closed tank, Venturi type and piston pump. All of them are water driven by the operating pressure of the system.

Distribution Pipelines (main-line, sub-main, lateral)

Distribution pipelines for irrigation systems include the mainline, sub-mains, manifold and laterals Plastic pipe is preferred because it has a higher resistance to corrosion, and its good friction loss characteristics (due to the smooth inner surface).

Friction loss is the loss of pressure caused by friction between water flowing through the system and the pipe walls.

The rougher the inside of the pipe, the higher the pressure loss due to friction will be. Friction loss is determined by the flow, length of pipe, and size of the pipe’s internal diameter, and the type of pipe.

It is important to use the correct friction loss tables for the chosen pipe. Use the manufacturers’ friction loss data if possible. Flow velocities of more than three meter per second (m/s) should be avoided when selecting the size of pipe. When there are multiple evenly-spaced outlets along a supply pipeline, as often is the case in lateral line, the friction loss is a fraction of the friction loss in the same pipeline with only one outlet.

In irrigation design, pipe sizes are specified based on economic, friction loss, water hammer considerations and flushing concerns. As pipe size increases, friction loss decreases (reduced pumping cost) but initial cost increases.

Emitters

There are several basic types of water delivery devices unique to micro-irrigation. They are designed to discharge water at low flow rates through small openings. The application rate of water is very small and slow. The discharge rate per emitter is usually given in US gallons per hour or liters per hour (ranging from 0.5 to 25 gph or from 1.0 to 4.0 lph). Operating pressure ranges between two and 60 psi depending on the type of emitter (see manufacturers’ specifications). Emitters can also be pressure-compensating, which means discharge rates remain relatively constant over a range of pressures.

Monitoring and Control Equipment

Backflow prevention valves and check valves are safety devices installed downstream from the pump or pressurized water supply. Backflow prevention valves are needed when low pressures can develop and allow contaminated water from the irrigation system to flow back into the water source and when dirty water can be sucked back into lateral lines thereby causing plugging of the emitters. Often considered optional equipment with irrigation systems, they are standard equipment on public water supplies.

They are also necessary when chemicals or fertilizers are being injected into the system.

Vacuum breakers or air release valves are another type of safety device that allow air into the header lines when the system is shut down. This prevents damage to the pipelines and prevents soil particles

from being drawn back into the emitters. They are required for underground installation of dripper lines and are recommended for all irrigation systems.

Valves are used in irrigation systems to control and direct the flow of water. They include gate valves, ball valves and solenoid valves (for automatic operation).

Pressure regulators are used to maintain a desired pressure and flow rate for non-pressure compensating emitters and drip tape. There are preset (non-adjustable) and adjustable pressure regulators. Pressure

regulators are often used throughout (usually at the start of sub-main pipelines) the trickle system to stabilize pressure due to elevation differences or high-water pressure.

Flow meters are often installed to monitor system flow rate. It is important to keep track of operating flow rates to find problems before they become serious. A reduction in flow may indicate plugging problems and an increase in flow may indicate a line break.

Pressure gauges are used as a visual aid to monitor pressure throughout the system. Gauges are generally placed at the pump discharge: one on each side of the filter to indicate when cleaning is

necessary, and one in each sub-main throughout the system. Pressure gauges provide a quick reference as to whether or not the system is operating at the correct pressure. Reduction in pressure indicates plugging of filters, while an increase in pressure may indicate a faulty pressure regulator.

Irrigation controllersare devices that use timer clocks to automatically turn irrigation equipment off and on at preset times. The type of controller selected depends on the number of devices it must control.